SupDragon Carbon Neutral Solution

Our carbon practice

As a compressed air system service provider with a history of 20 years, especially for compressed air systems in high-energy-consuming industries, our service goal is to keep pace with the society’s carbon neutral goals. For this reason, we have been committed to the continuous improvement of energy-saving technologies. Explore, innovate and promote, and through our innovative services, help customers improve the efficient use of energy.

■ From 2016 to 2020, through the GAS® energy-saving services we provide, we can save 310 million kilowatt-hours of electricity and reduce carbon dioxide emissions by 310,000 tons.

■ For the high energy consumption air compression industry, energy saving and emission reduction are imperative

》Air Compression System "Carbon Data"

The following data is based on national statistics in 2020

National total power generation 74170 Billion kWh | energy used 450 billion kWh of electricity | The average energy saving of the system can reach 90 billion kWh of electricity | Can reduce carbon dioxide emissions 89.73 million tons |

Take a user with an installed capacity of air compressor of 1000kw as an example

Annual system energy saving can reach 1.6 million kWh | Can reduce carbon dioxide emissions 159.52 tons | Equivalent to planting a broad-leaved forest 65 acres |

》Through years of carbon neutral practice, we have formed a series of carbon neutral solutions:

Energy-efficient products Improve energy efficiency by 5%~15% | Frequency conversion technology Reduce energy waste by 20%~35% | Engineering optimization Reduce energy consumption by 5%~10% |

Digital Intelligent Control Reduce energy consumption by 3%~5% | Heat recovery and utilization 75%~94% of consumption can be recovered | New energy Utilization of energy such as solar energy |

》Mature and efficient screw compressor

The cornerstone of our carbon neutral solution is mature, efficient, and technology-leading energy-efficient products, including our self-developed S series two-stage compression oil-injected screw compressors and SO series oil-free screw compressors/fans. Key components are used The technologically advanced rotor profile mainframe is equipped with high-efficiency IP54/IP55 permanent magnet motors, which can increase the compression efficiency by 5~12% under the same power consumption.

|  |

S series oil-injected screw compressor station | SO series oil-free screw compressor station |

》Technology-leading centrifugal compressor

Speed-increasing centrifugal compressors provide large-displacement and higher-efficiency oil-free compression solutions, with a maximum compression efficiency of 10-15%; air-floating and magnetic-levitation centrifugal compressors provide medium and small displacement, high-efficiency oil-free compression solutions The solution can increase the compression efficiency by 5~8%.

|  |

Speed-increasing centrifugal compressor station | Air-floating centrifugal compressor station |

Frequency conversion technology

》Permanent magnet variable frequency motor matching broadband frequency converter

The screw compressor adopts IP54/IP55 grade, low-speed 4-stage permanent magnet variable frequency motor, equipped with dedicated broadband inverter drive and constant voltage energy-saving logic control maglev, air-floating centrifugal compressor adopts IP55 grade high-efficiency permanent magnet variable frequency motor, equipped with high frequency Inverter drive and constant voltage energy-saving logic control.

■ Accurate, fast and stable adjustment of output flow to match working conditions

■ It can realize the widest 25~100% range of exhaust volume adjustment, reduce no-load energy consumption loss, and

save energy up to 15~35%

■ The system pressure is stable, without pressure adjustment and energy consumption loss, which can reduce the energy

consumption loss of pressure belt by 2~3%

■ The frequency conversion starts smoothly, reducing the impact on the grid caused by the instantaneous current surge

》Scientific system detection and design

The air compressor system energy-saving program is based on the accurate detection of the system. Through years of rich project experience, we have mastered scientific system detection methods, including professional instrumentation facilities and scientific detection technology. Our program design is tailored based on the detection data. , To ensure the scientific feasibility of the program at the source.

》Adaptation of equipment and auxiliary facilities

The equipment selection plan is adapted according to the customer's working conditions, and the engineering auxiliary equipment and facilities are adapted according to the equipment and working conditions. This design minimizes system losses and waste while ensuring that the customer's production conditions are met. Ensure safety and economic efficiency.

》Professional design of engineering pipelines

Through the scientific adaptation of equipment and auxiliary systems, the engineering pipeline can be optimized and simplified to the greatest extent. At the same time, the professional design and construction of the engineering pipeline can minimize the pressure drop loss and leakage of the pipeline.

■ Matching equipment and working conditions can reduce energy consumption by 8-20%

■ Engineering pipeline optimization can reduce energy consumption by 3~7%

Digital intelligent control management

》"SupDragon Cloud" IOT Digital Intelligent Control Management System

Realize the on-site centralized management and remote monitoring of compressors. Through logic operation and PLC control, it has the function of optimizing the operation combination of equipment on-site, which can optimize the economic operation combination of equipment according to the on-site working conditions and reduce the energy consumption of unit unloading and pressure band loss; At the same time, the energy consumption data of the system can be remotely monitored and alarmed online.

■ Optimized combination of equipment on site can reduce energy consumption by 3~5%

■ Online and remote monitoring of system energy consumption indicators at all times

Working matching Optimized operation | Real-time monitoring Pre-alarm | On-site remote Real-time online | Data file Seamless |

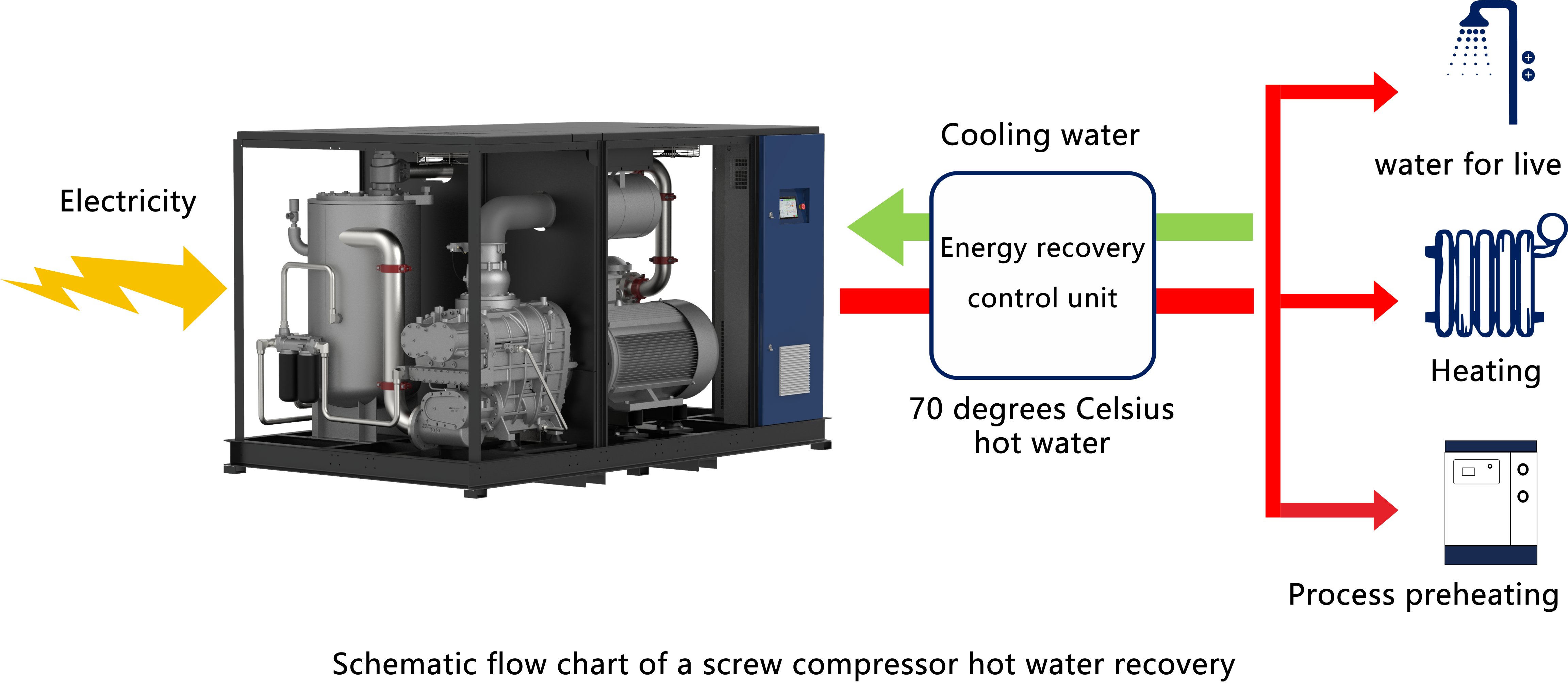

》Energy recovery with hot water

The production of compressed air consumes a lot of energy, of which 94% of the energy consumed is converted into heat and discharged through heat exchange equipment. Through the heat exchange technology, we can recover the heat energy of the compressor in the form of hot water, and we can greatly reduce fuel consumption and carbon dioxide emissions, saving a lot of energy and expenses.

■ Oil-injected screw compressors can recover 75% of energy consumption

■ Oil-free compressors can recover 94% of energy consumption

■ It can also reduce the energy consumption of the cooler by up to 5%

■ The recovered hot water is used for domestic hot water, heating, process waste heat and lithium bromide air conditioning

|  |

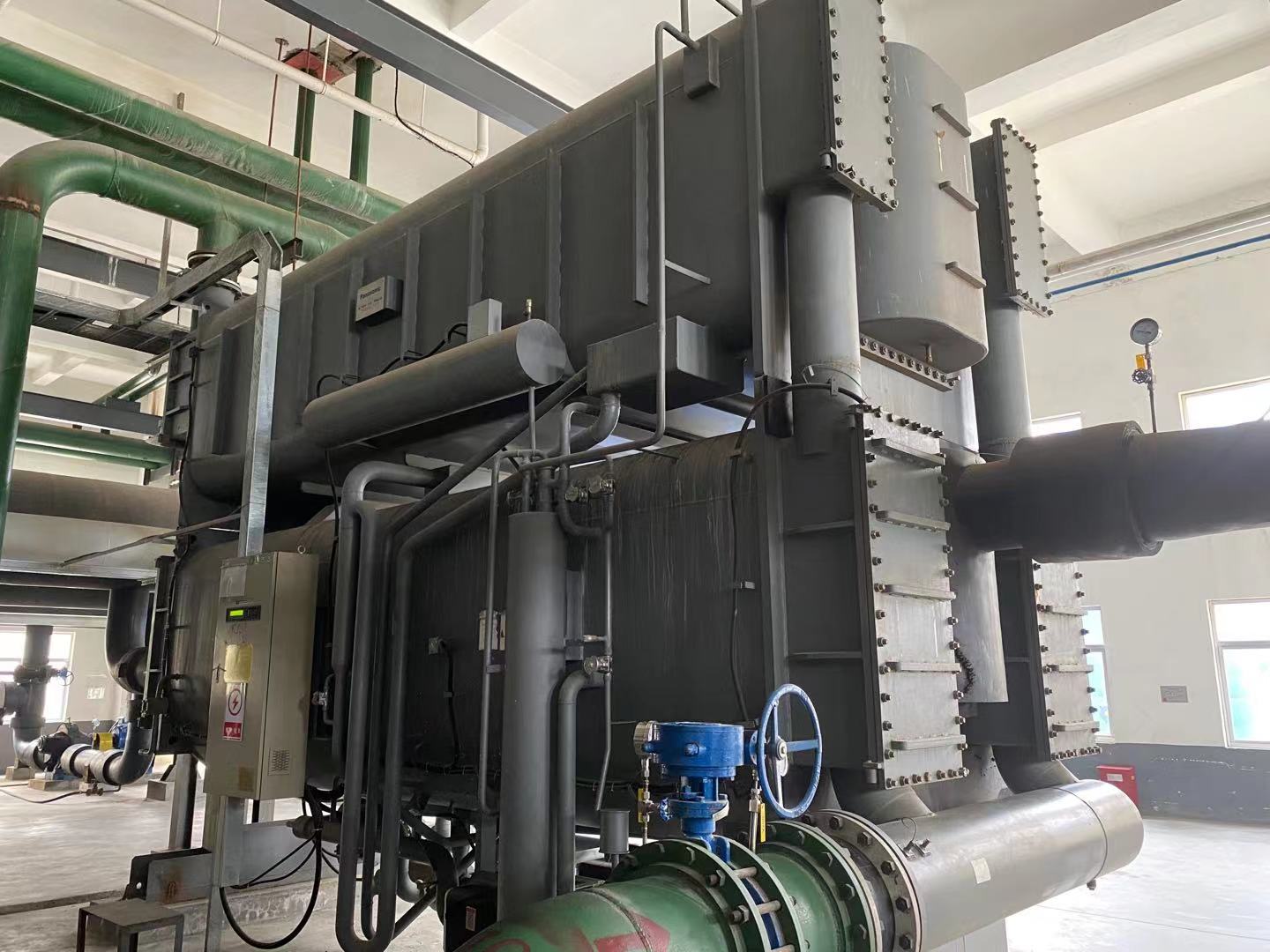

Hot water recovery for domestic water and process preheating | Hot water recovery for lithium bromide air conditioners |

Heat recovery

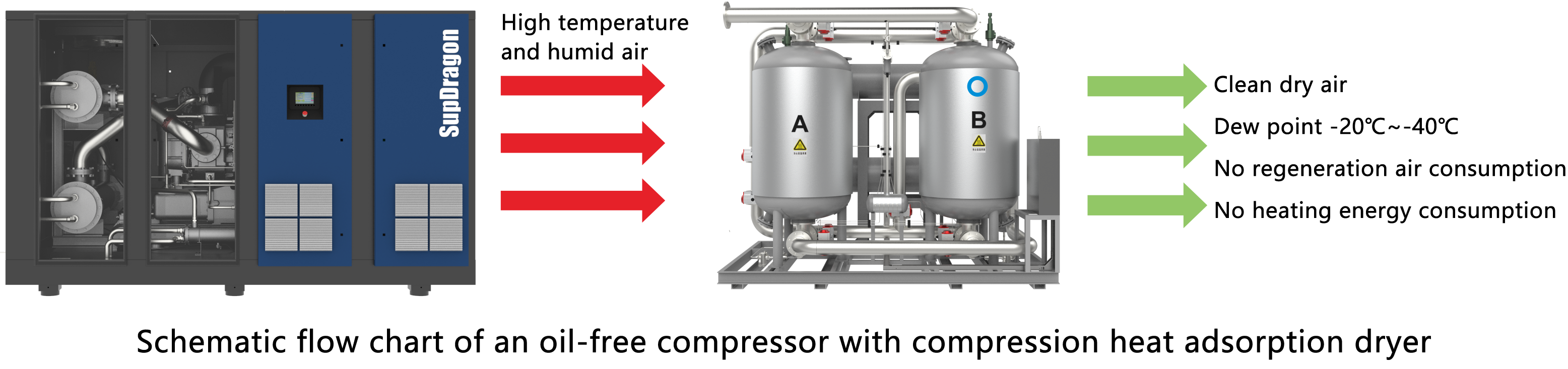

》Compression heat recovery for regeneration of adsorption dryer

Select the high-temperature air type and configure the DAR compression heat adsorption dryer, use high-temperature oil-free compressed air to heat the regeneration adsorption desiccant, so as to obtain low dew point dry air. This process has no refrigerant, no heating energy consumption and compressed air consumption for adsorbent regeneration. It is the best solution for compressed air drying at present.

■ Oil-free air suitable for oil-free screw and centrifugal compressors

■ Can reduce up to 18% of the renewable energy consumption of the adsorption dryer

| |

Compression heat recovery of centrifugal compressor for regeneration of adsorption dryer |

Heat recovery

》Steam turbine driven compressor

Power plants and large chemical plants generally have their own power plants. By-product steam can be used for steam turbines to drive large compressors. Turbine driving has a higher energy consumption rate than motor driving: the motor is driven by the steam from the boiler first. It is necessary to supply the motor to drive the air compressor after power generation by the steam turbine of the power plant; the drive of the steam turbine can reduce the loss in the energy conversion process and improve the energy utilization.

■ Conducive to the balance of steam consumption in power plants, effectively reducing energy consumption costs

■ Reduce the power grid requirements for electric drive start of large compressors and reduce the cost of starting devices

■ It is convenient for variable load adjustment of large compressors, and overcomes the difficulty that large motors are not suitable for frequency conversion adjustment

Steam turbine compressor station of thermal power plant

》Photovoltaic power is used for power supply of air compressor station

Using photovoltaic power generation clean energy to supply power for air compressor stations, through 1-10MW distributed photovoltaic power generation projects, it can provide air compressor stations with clean energy of 10 million kWh to 100 million kWh each year.

》Ground photovoltaic power generation and distributed photovoltaic power generation

It can be engaged in the design and general contracting business of 100MW-level ground photovoltaic power generation and distributed photovoltaic power generation projects.

■ Use clean energy to better protect our environment

■ Practicing green development, advocating environmental protection concepts, and building a green home together

Focus on US